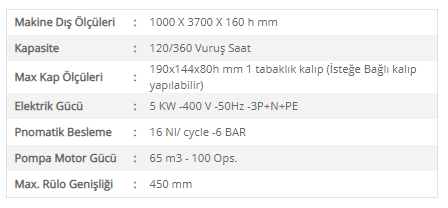

Fully Automatic Bowl Sealing Machine KV-1000

FUNCTIONS OF THE MACHINE

UNLOADING AND LOADING STATION:

The plates placed in the station with two chambers are pushed into the slot with the help of the operator, after the product is detected by the sensors, the operation begins and the vacuum / gas / bonding process is performed. The operation continues by removing the finished plates and placing new plates.

FILM WINDING SYSTEM:

The upper film sticking process of the bowls taken into the chamber through the loading station takes place, while this process takes new films into the chamber by means of automatic film winding engines, the residual films are collected on the other side of the machine.

GLUE / CUT DIE STATION:

The film, which is drawn on the bowls in the chamber by means of film winding motors, is adhered to the bowl in the mold by means of pneumatics and valves, and again with the help of pneumatics and valves, film cutting processes are made to the plate dimensions and the mold is opened.